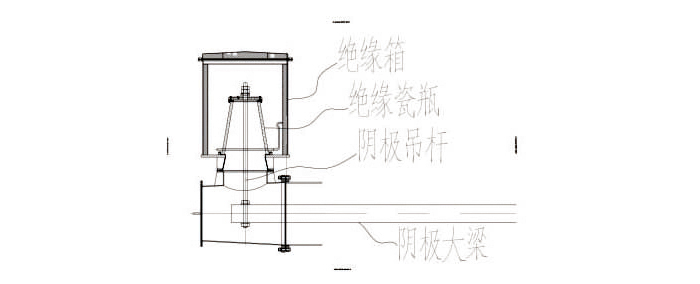

Insulation system

The flow rate of the flue gas in the wet electrostatic precipitator is generally 2m/s~3m/s. The upper and lower beams are fixed to ensure the cathode line is in the center of the anode tube, and the vibration and displacement caused by the disturbance of gas flow are as small as possible. The upper end of the cathode wire is fixed on the upper cathode trabeculae, and the cathode trabeculae are connected to the upper cathode beam. The lower end of the cathode line is fixed on the lower cathode trabeculae, and the cathode trabeculae are connected to the lower cathode beam. And the tensile strength of each pole is consistent in the installation. The cathode beam passes through the insulating box pipe of the 600mm diameter of the tower wall and hangs inside the insulation box. In the wet flue gas conditions, to prevent water condensation in flue gas bottle caused creepage, ensure the cathode suspension insulator shall be kept dry, hot air blowing system. The system is composed of a sealing fan, a heater, a valve and so on. The heater is heated by electric heating or steam heating in two ways. The experimental hot air temperature is set at 80 C, which ensures that the inner wall of the insulator is dry, and it does not affect the scale of the anti-corrosion glass. In order to achieve the purpose of drying insulators with small air volume, we have improved the internal structure of insulators to improve the insulation performance.

The effect of the insulation box into the hot air

1. the fog droplets and dust in the flue gas are prevented from entering into the insulation box through the insulator casing, and the corrosion in the insulation box is caused by condensation.

2. prevent wet flue gas from entering the insulation box, and the surface of the casing is struck by electric shock.

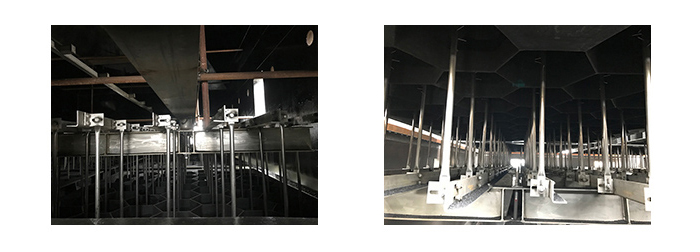

Anodic beam

Upper and lower cathode frame

Gas uniform board

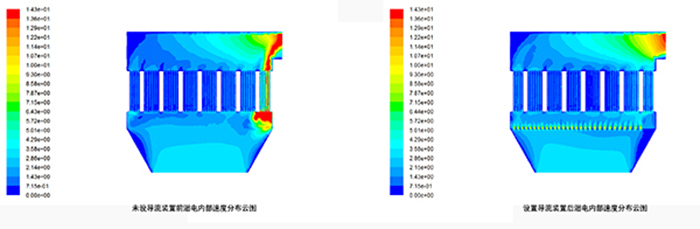

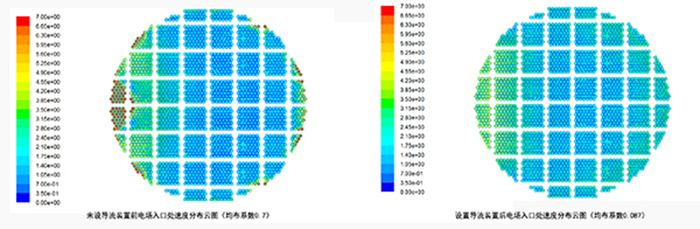

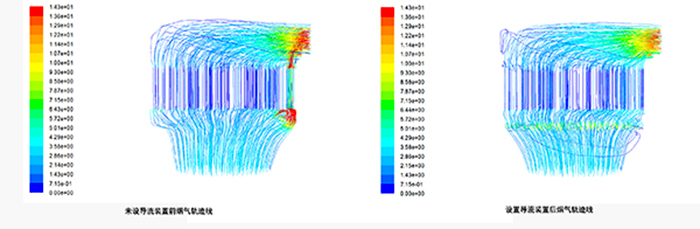

The distribution of flue gas flow field in wet electrostatic precipitator is one of the main factors that affect the efficiency of electrostatic precipitator. Through numerical simulation, we study the distribution of airflow to simulate whether the air distribution device of wet electrostatic precipitator can meet the uniform distribution of airflow in electric field.

O. Through the design of the air distribution plate inside the wet electrostatic precipitator, we can adjust the flow field distribution of the flue gas, so as to achieve the desired air distribution structure for the ideal airflow distribution, and provide a basis for product design.